Products Description

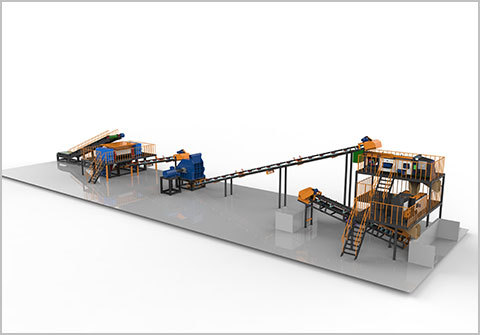

TOFON Line

According to the characteristics of complex working conditions, nonlinear conditions, variable time delay and multi-variable coupling in the whole process of the production line, TofonEP determines the key factors affecting the on-site production process through advanced detection means, and uses the advanced neural network and support vector machine algorithms independently developed by the company in the field of automatic control to estimate the key data. Establish soft sensing models for crushing, grinding classification, flotation process, etc. At the same time, through the correlation analysis of field data, combined with the production process, the application of expert rules, fuzzy control, rule self-learning and other technologies, form an expert system to realize the optimization control of the whole process. The automatic control system of the whole process stabilizes the production process and balances the operating capacity and efficiency of each process. Under the premise of ensuring the production index, reduce the production cost, improve the processing capacity of the plant, reduce the labor intensity and improve the working environment.

Processing Flow For Reference

GENERAL DOUBLE LAYER SIMPLE PROCESSING

GENERAL SIMPLE PROCESSING

SCRAP ALUMINUM RECYCLING PROCESSING FLOW

SCRAP ALUMINUM RECYCLING PROCESSING FLOW 2

SCRAP STEEL PROCESSING FLOW

Why Choose Us

Safe

1. Safety considered magnet design;

2. All covered moving parts,

3. Safety standards Strictly complied.

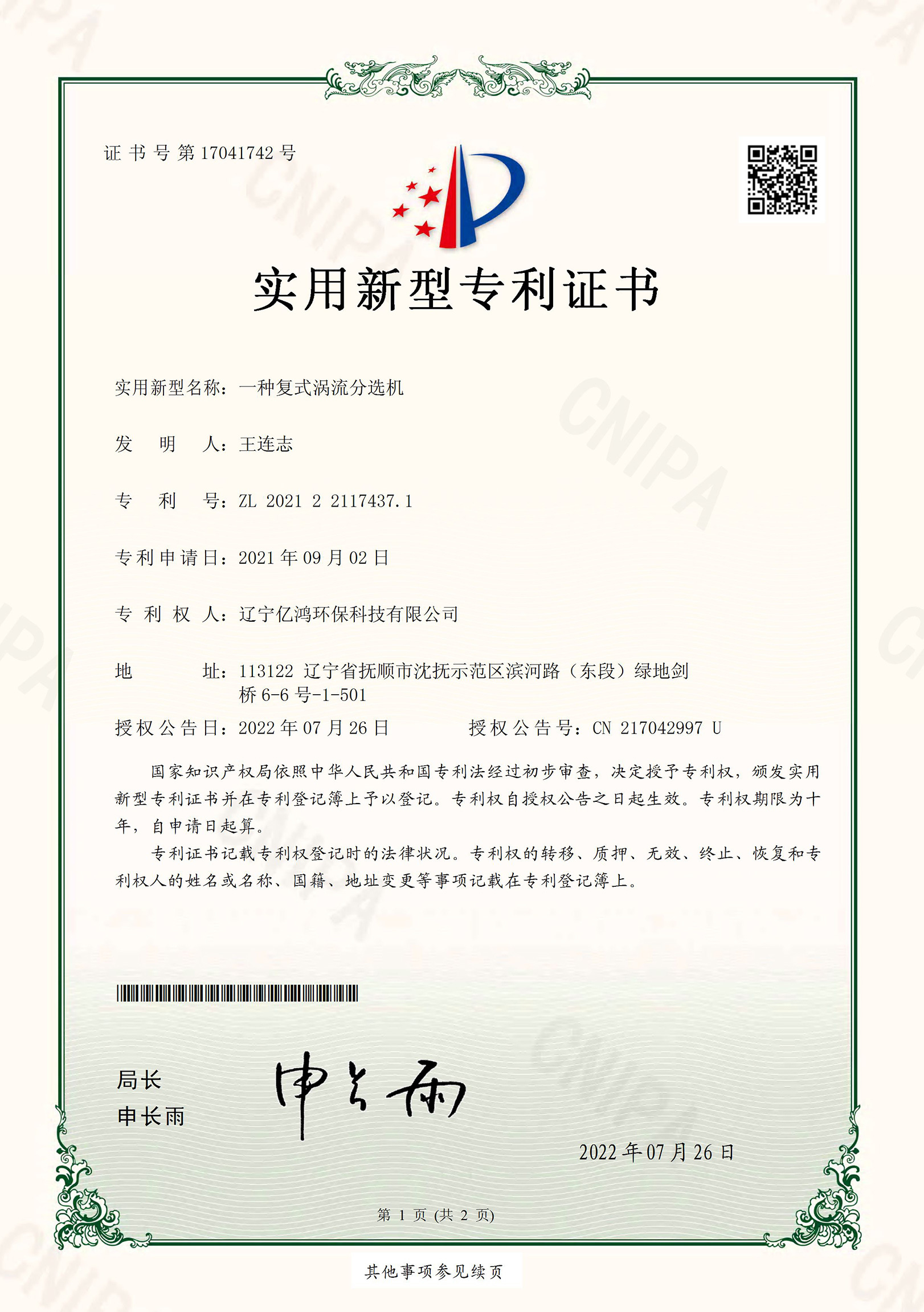

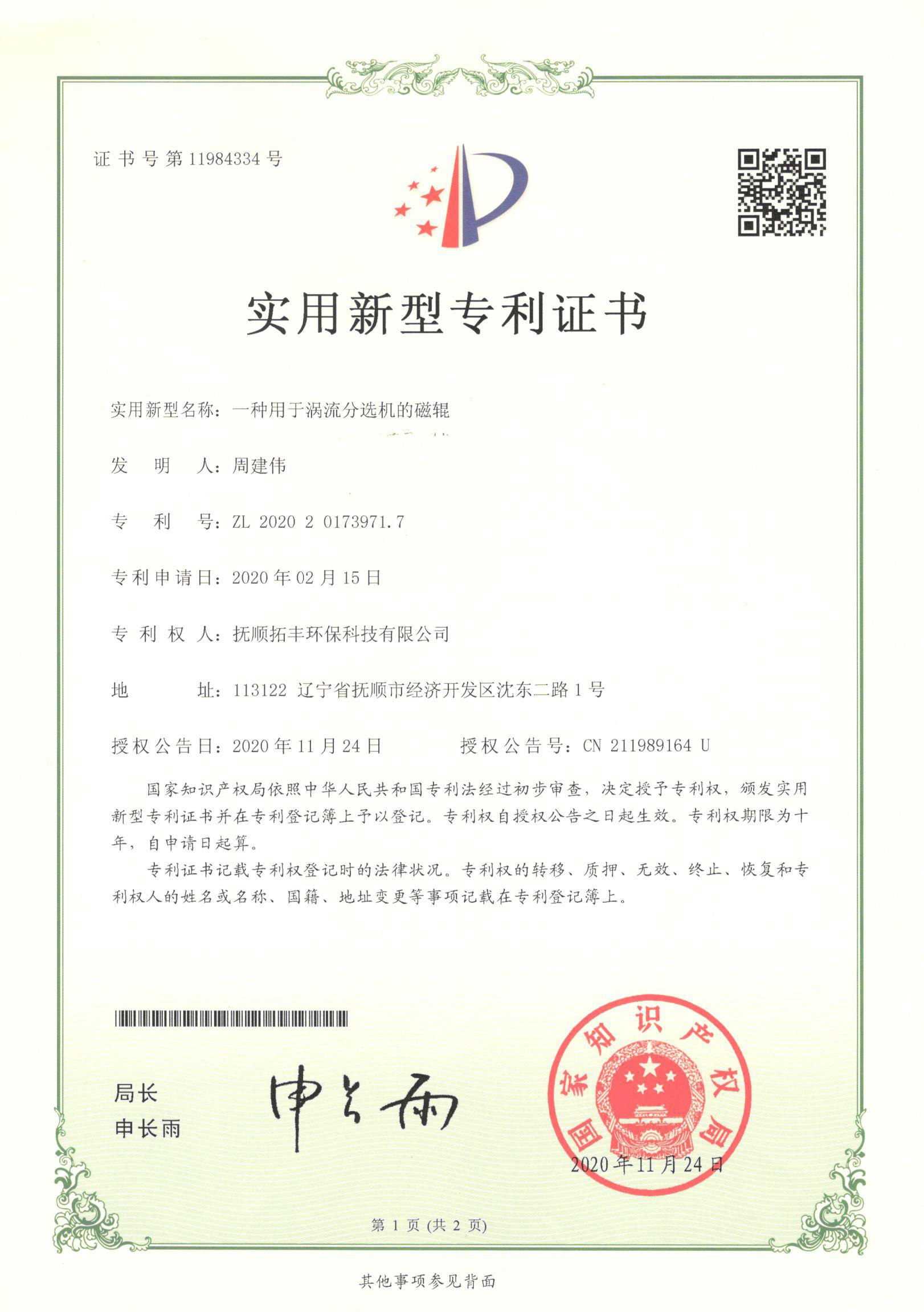

Reliable

1. Patented durable magnet technology,

2. Real material strict process;

3. Multi special surface treatment.

Advanced

1. Continuous unique innovation,

2.20 empirical improvements;

3. Intelligent control system

Company Profile

Protecting Resources Together.

Welcome to the world of TOFON EP! Resource utilization is the present of human beings, the environment is the future of human beings. How to balance two sides? Environmental protection is the fulcrum. TOFON EP's philosophy is to use our technical advantages to contribute to the future of human beings in the field of environmental, waste recycling, and

resource protection! TOFON EP was established in 2016, focuses on the provision of products and complete recycling solutions. The business begun with the core technology of high-frequency eddy current. Now it develops into a supplier of products and services such as Eddy Current Separator, Metal Sorter, X-Ray Sorter, Magnetic Separator, Air Sorter and

Whole Lines engineering. The products are widely used in the recovery process of power plant slag, steel scrap, recycled aluminium, electronic waste, lithium battery, vehicle, glass, paper and other industries. Countless developmental tests, perennial field tracking ensures an excellent performance of the product. At the same time, we also provide the complete

support to meet the needs of partners in planning, processes, logistics, and engineering construction. TOFON EP hopes to offer a type of services, which are based on a better understanding of the clients! We respect, listen to and support our partners, fulfil the requirements of partners and take pride in being a part of environmental protection. For the partners, for the environment, for the future! Protecting resources together!

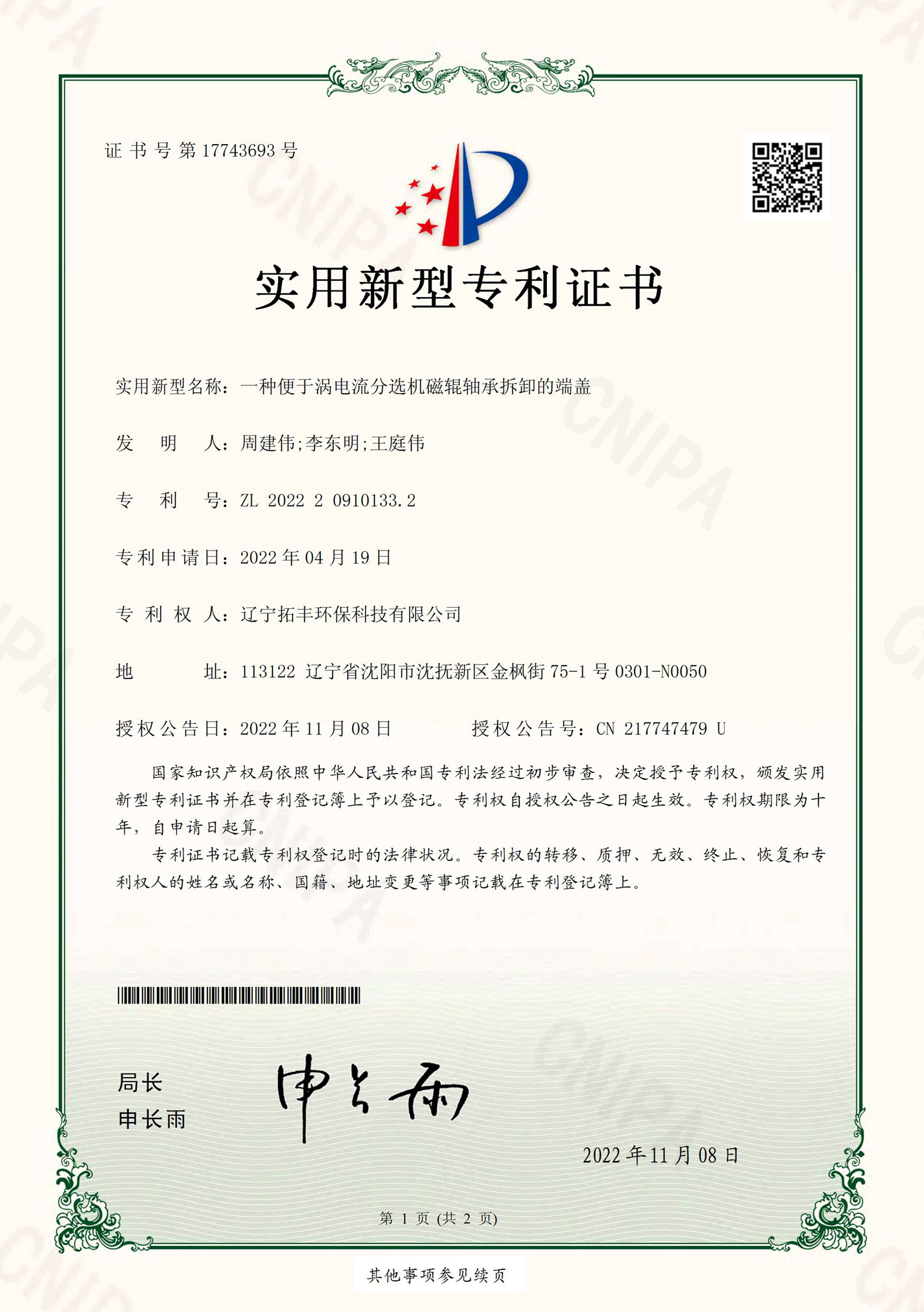

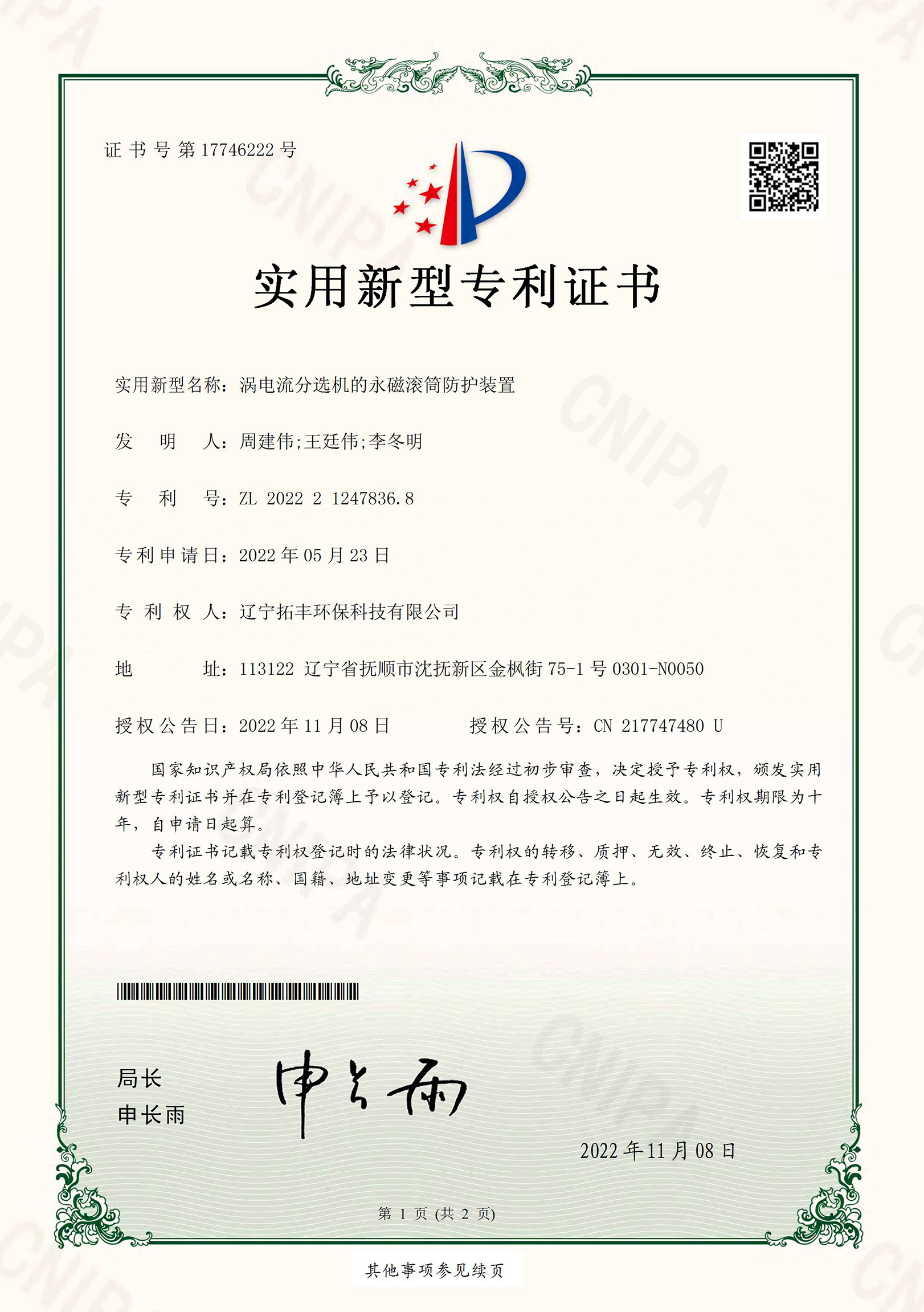

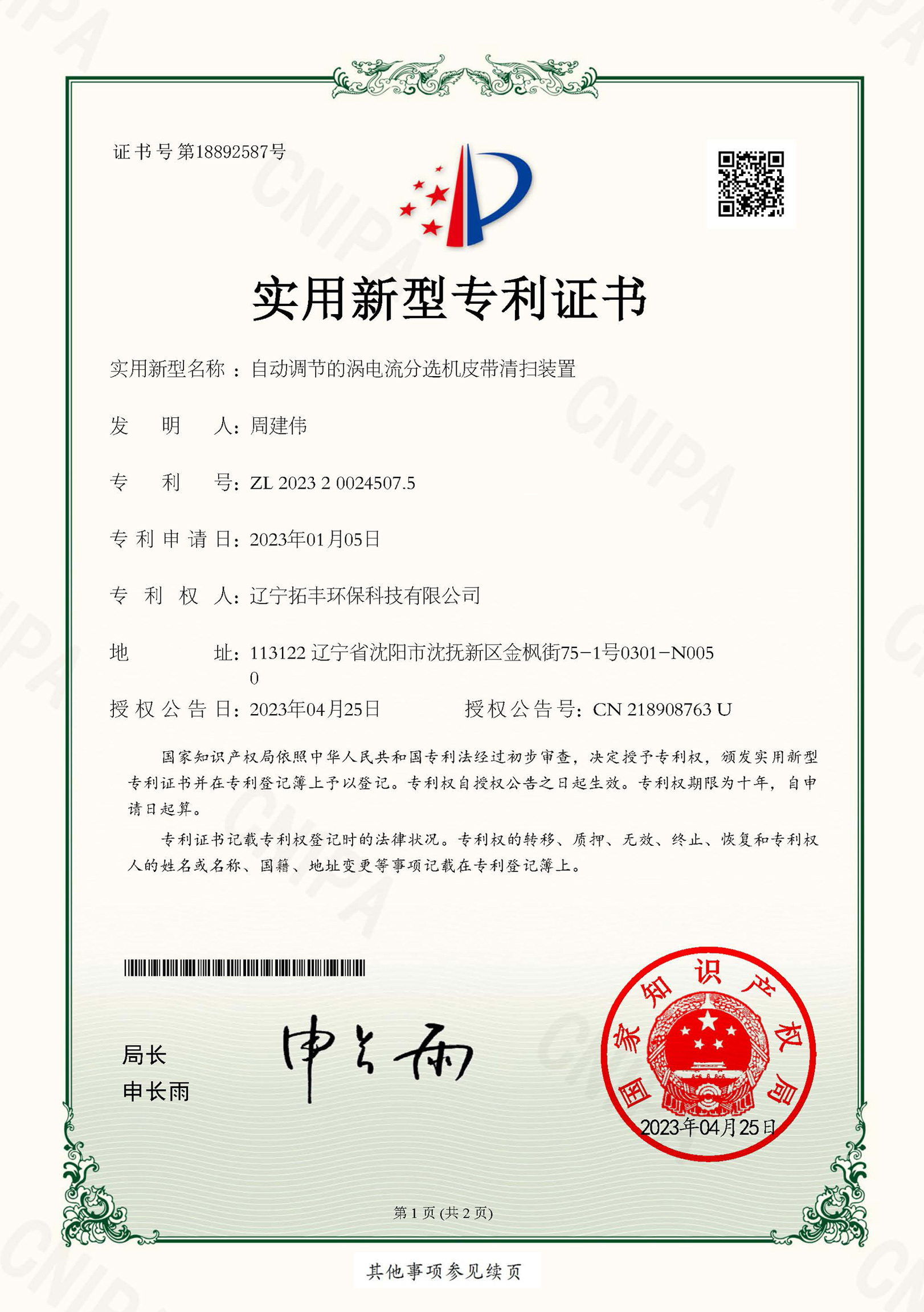

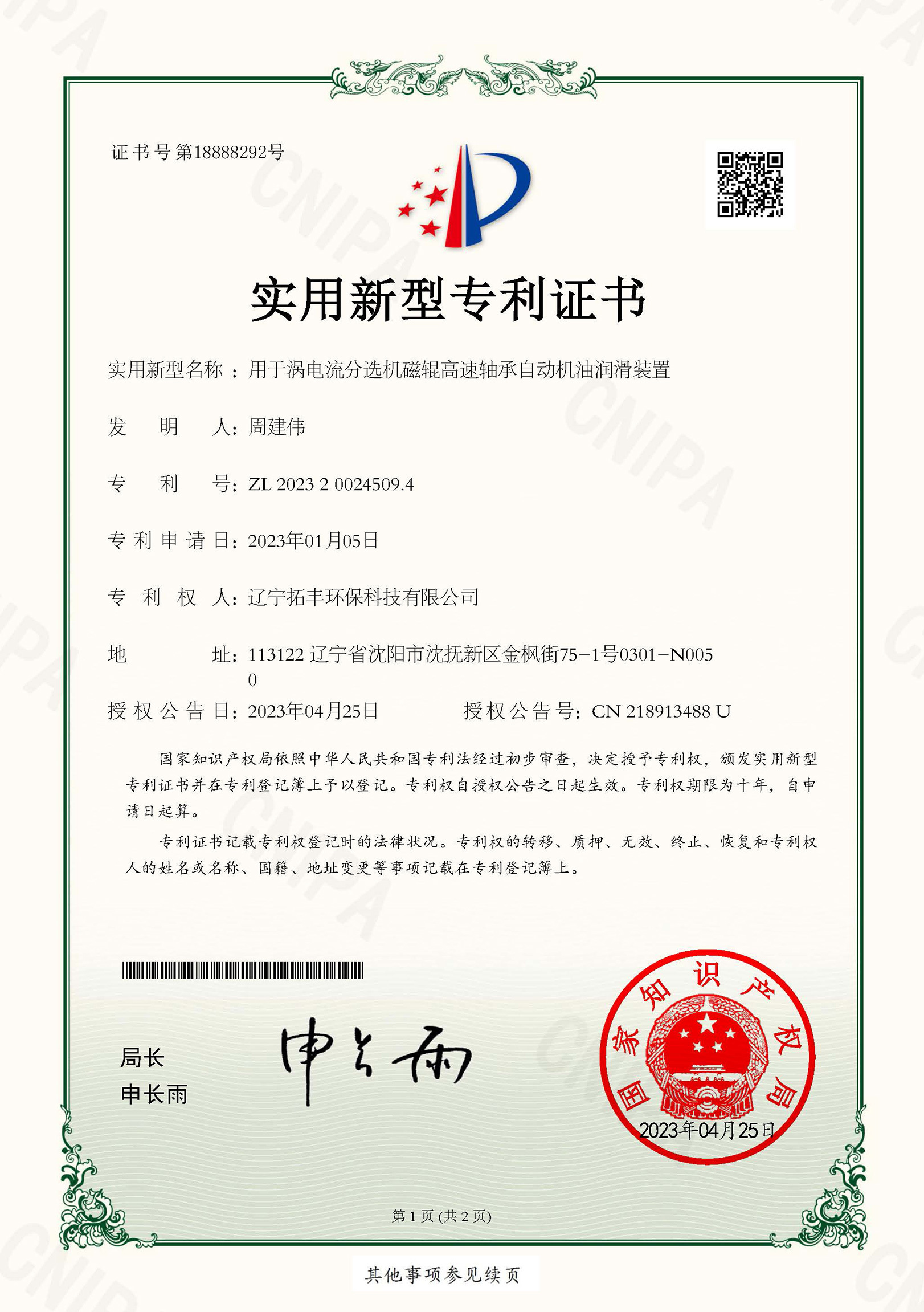

Certifications

Application

FAQ